The Future of Construction: 3D Product Design and CNC Technology

From Design to manufacturing and building

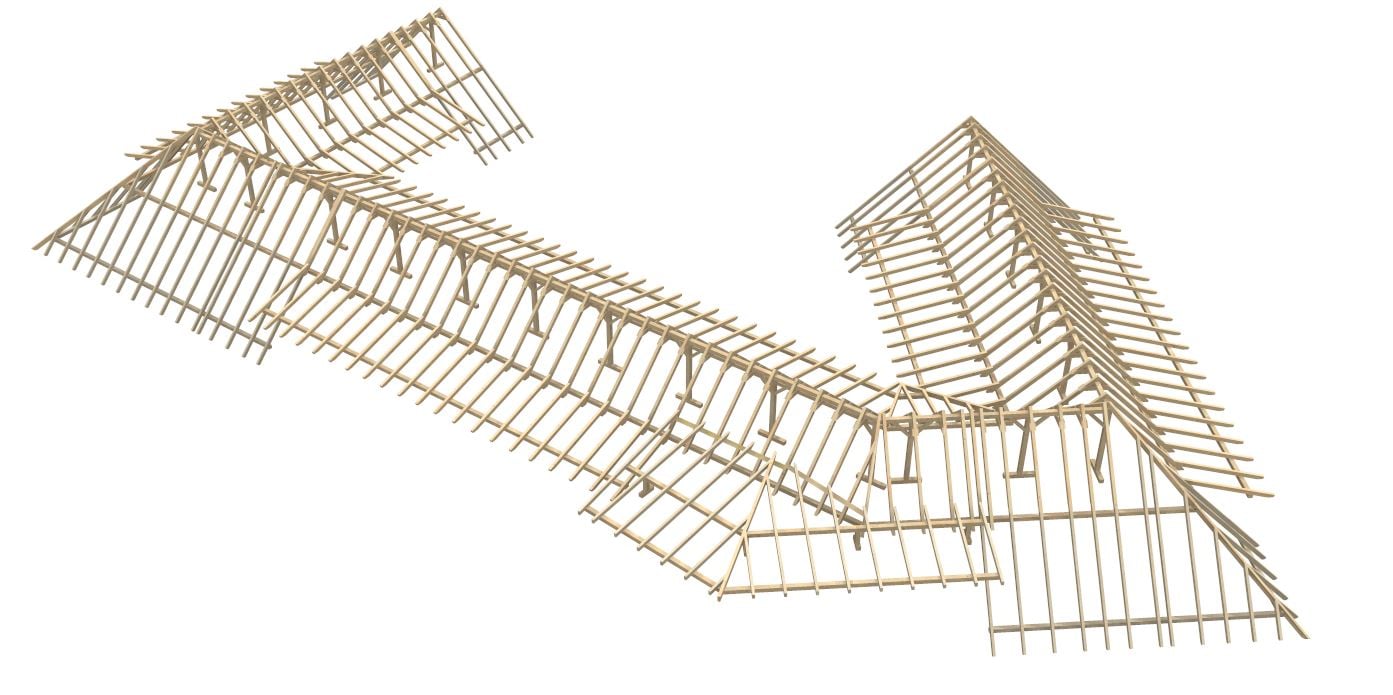

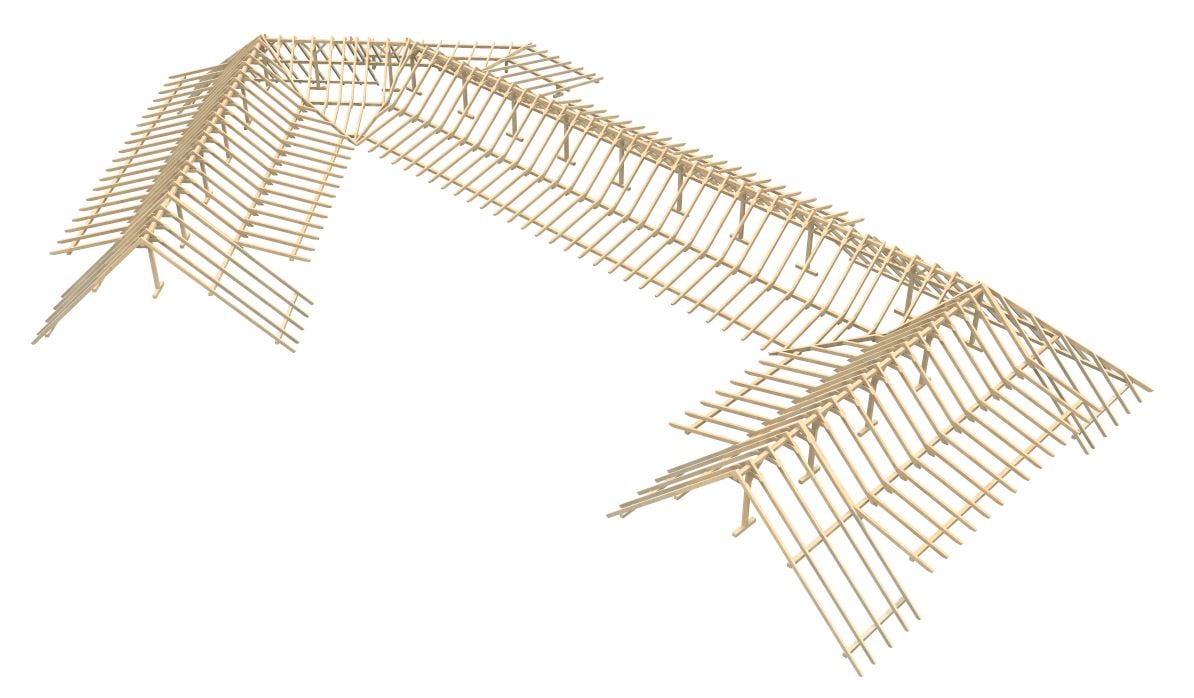

The pictures show the roof structure of an apartment building under construction. When it comes to constructing precision and efficiency are of utmost importance.

The Project Begins: 3D Product Design

Every great construction starts with thorough planning. During the creation of the roof structure of the apartment building shown in the pictures, we utilized 3D product design. This process allows us to examine and refine the plans in a virtual environment before even cutting the first piece of wood. 3D design not only prioritizes aesthetics but also functionality and structural stability.

- Planning

- Application of timber joints

- Placement of holes

- Milling out the location for the fascia board

- Minimizing material waste

Processing: CNC-controlled, 5-axis machining center (Hundegger K2i)

After the design phase comes manufacturing, where the Hundegger K2i, a CNC-controlled, 5-axis machining center, takes center stage. This machine is one of the most advanced pieces in the woodworking industry, capable of precisely cutting complex geometric shapes, accurately determining the placement of holes, and milling out the location for the fascia board.

A Dream Under Construction

The roof structure of the apartment building we presented is just one example of how we can bring the architectural solutions of the future into the present. We are proud to execute every step from 3D product design to CNC-controlled machining at a high level. Our goal is to ensure that the buildings we create are not only beautiful and rich in functionality but also sustainable and resilient over the long term against the test of time.

- Tetőszerkezet